|

Model |

Product name | Temperature tolerance grade | Voltage |

|

GN-350 |

Bare Cu/Glassfiber/Mica/GF |

350°C |

600V |

| GN-450 |

nickel-plated Cu /Glassfiber/Mica/GF |

450°C |

600V |

|

GN-500 |

Pure nickel wire/Glassfiber/Mica/GF | 500°C | 600V |

| GN-1000 |

Copper/Fireproof silicon/Silicon |

1000°C | 600V |

Fire resistant wire-GN450

Fire resistant wire-GN450

- Product Item : Model no.:GN450

- Rated voltage:300/500V

- Working temperature:-60~+450℃

- Conductor:Twisted pure nickel wire

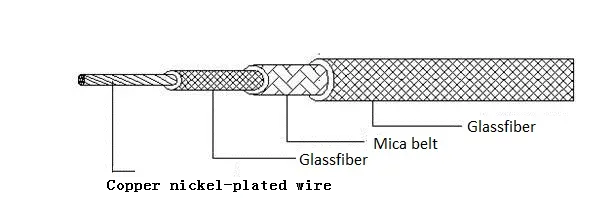

- Insulation:Glass Fiber Braided + Fluorophlogopite Belt+Glass Fiber Braided

- Product description:fire resistant wire

Fire resistant wire and cable (Fireproof wires, Fire rated wires) can maintain the integrity of wire and cable lines and the normal operation of line equipment for a certain period of time while the external flame is still burning in the fire accident of wire and cable.

We use the Glassfiber+ Mica and Fireproof silicon materials to be the insulation.

Below is our fire resistant wire infor. of types,cable structures,specifications,etc.

If you have special requirements please feel free to message or email us!

Fire resistant wire types

Structure:

Characteristics/uses:

Fixed

laying, plus flame burning, no harmful and toxic gases. This product is a

kind of wire and wire used in various electrical devices which need

fire protection performance in metallurgical, thermal, petroleum,

chemical, natural gas, kerosene and other special environments.

Fire resistant wire Specification, structure and technical parameters:

|

Nominal cross-section area (mm2) |

Conductor structure |

Insulation thickness |

Outside diameter controlled |

DC Resistance of Conductor at 20 ℃ |

Packaging length |

|

0.5 |

7 × 0.30 |

0.5 |

2.3 ± 0.3 |

40.8 |

200 |

|

0.75 |

11 × 0.30 |

0.5 |

2.5 ± 0.3 |

24.3 |

200 |

|

1 |

14 × 0.30 |

0.5 |

2.6 ± 0.3 |

20.0 |

200 |

|

1.5 |

21 × 0.30 |

0.5 |

2.9 ± 0.3 |

12.6 |

100 |

|

2 |

28 × 0.30 |

0.6 |

3.3 ± 0.5 |

9.84 |

100 |

|

2.5 |

35 × 0.30 |

0.6 |

3.6 ± 0.5 |

7.37 |

100 |

|

4 |

56 × 0.30 |

0.8 |

4.7 ± 0.5 |

4.83 |

100 |

|

6 |

84 × 0.30 |

0.8 |

5.5 ± 0.5 |

3.26 |

100 |

|

10 |

84 × 0.40 |

0.8 |

6.6 ± 0.5 |

1.80 |

100 |

|

16 |

228 × 0.30 |

0.8 |

7.8 ± 0.5 |

1.31 |

100 |

|

126 × 0.40 |

0.8 |

7.8 ± 0.5 |

1.31 |

100 |

|

|

25 |

196 × 0.40 |

0.8 |

9.5 ± 0.5 |

0.758 |

100 |

|

361 × 0.30 |

0.8 |

9.5 ± 0.5 |

0.758 |

100 |

|

|

35 |

494 × 0.30 |

1.0 |

11.2 ± 1.0 |

0.548 |

100 |

|

50 |

396 × 0.40 |

1.2 |

13.2 ± 1.0 |

0.384 |

100 |

|

703 × 0.30 |

1.2 |

13.2 ± 1.0 |

0.384 |

100 |

|

|

70 |

551 × 0.40 |

1.2 |

15.4 ± 1.0 |

0.289 |

100 |

|

988 × 0.30 |

1.2 |

15.4 ± 1.0 |

0.289 |

100 |

|

|

95 |

760 × 0.40 |

1.2 |

17.4 ± 1.0 |

0.205 |

100 |

|

Note: According to the technical agreement between the two parties, products of other specifications can be produced |

|||||

Products Category

Latest News

CONTACT US

Tel/Wechat/Whatsapp:8613811300279

Email:sales@yiyuancable.com

Add:D4/F Bldg,Guijiao Park,No.355,LongJin Road,Lucheng road,Wujin Dis. ChangZhou,Jiangsu Province,China.